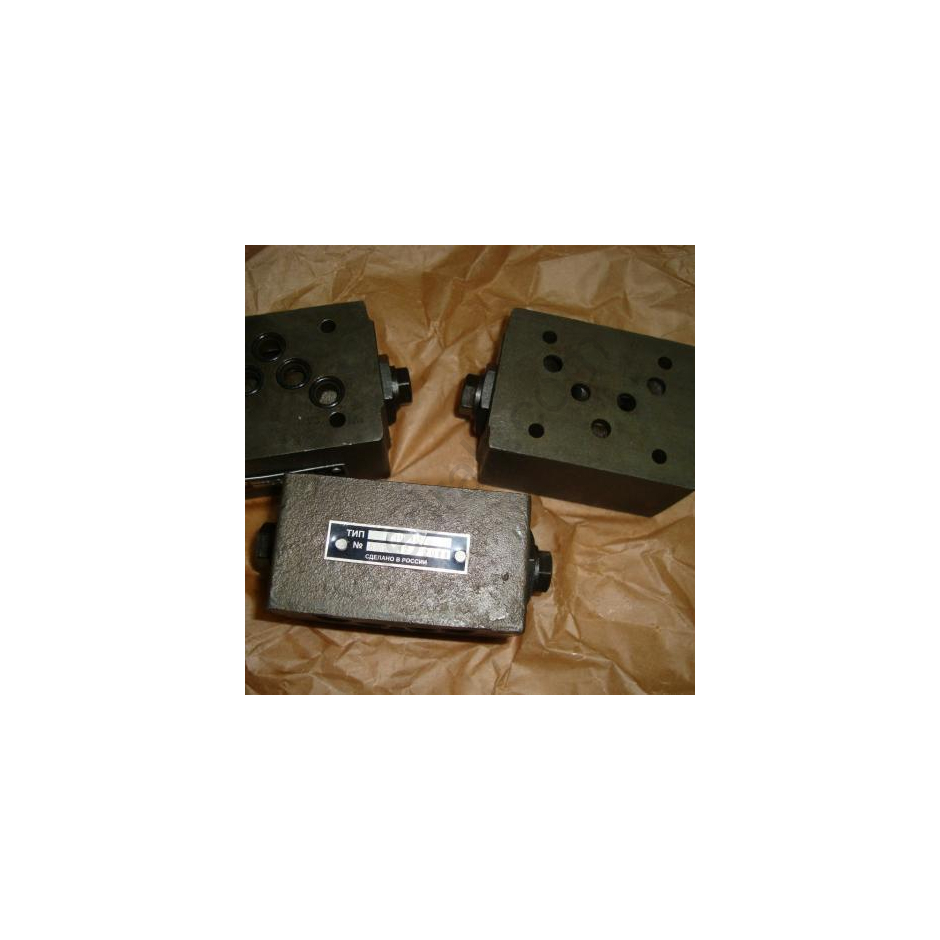

Hydraulic lock gzm 10/3, - 6/3

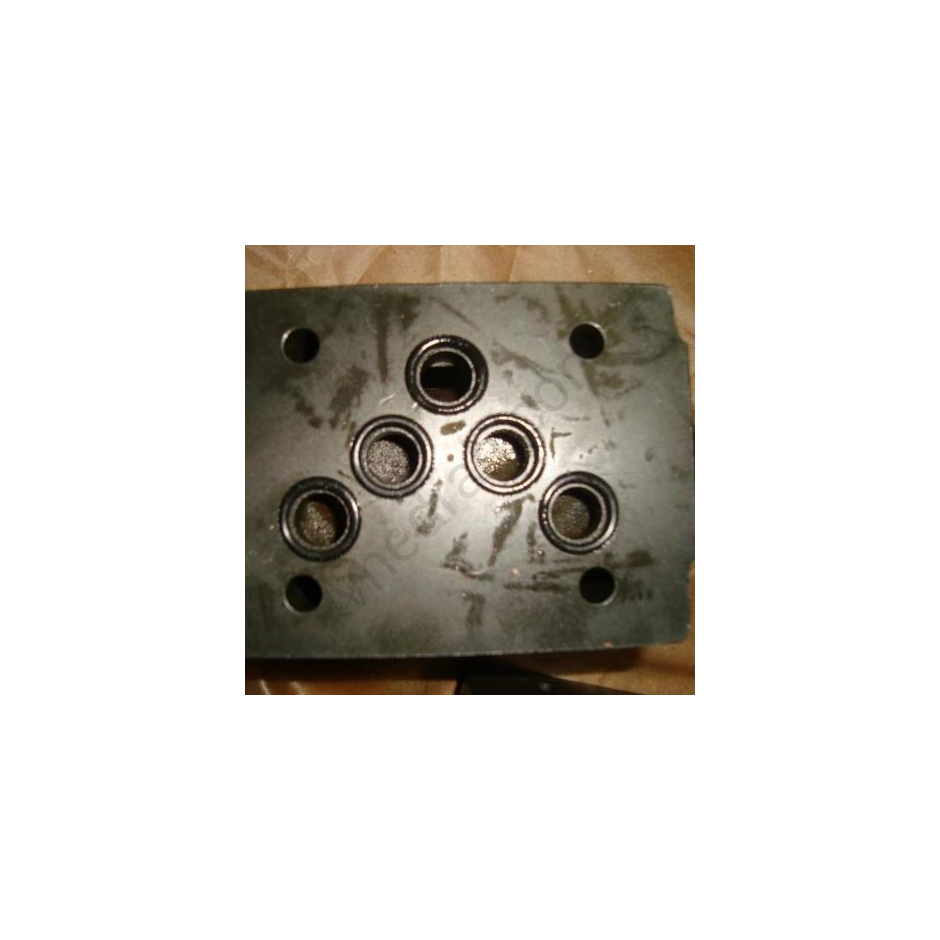

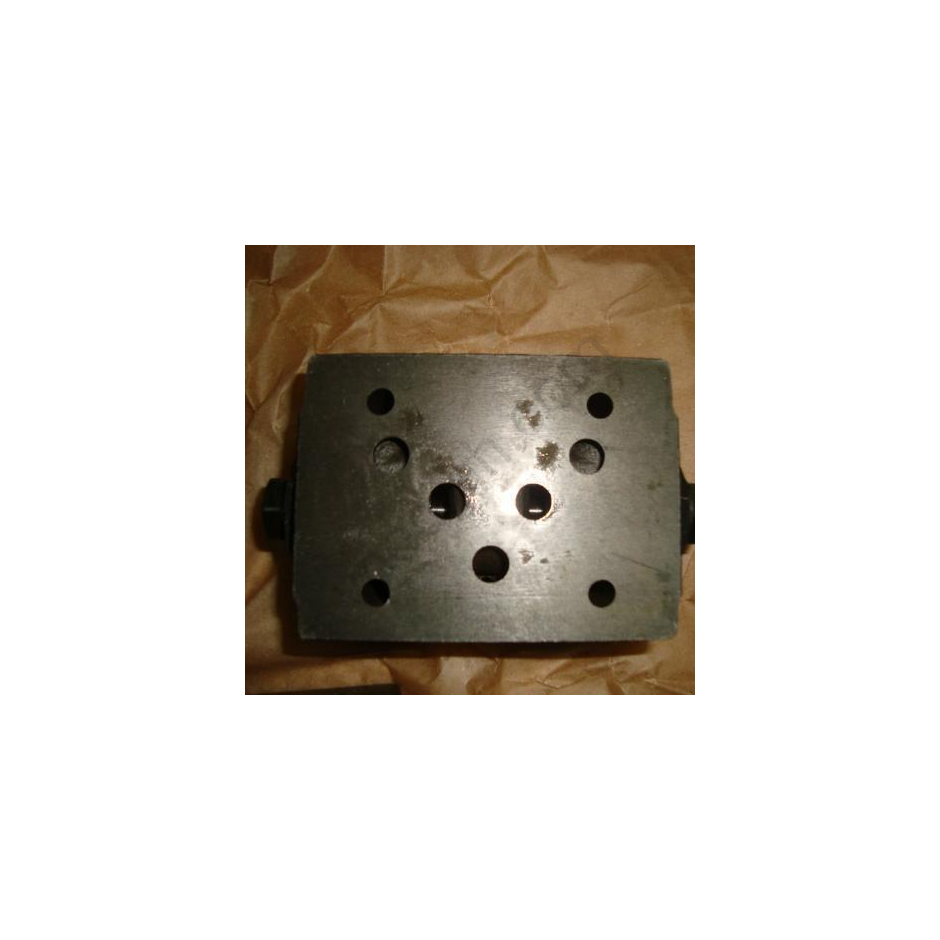

Hydraulic lock GZM6/3M, GZM10/3M, GZM102 of modular installationHydraulic locks GZM 6/3 M, GZM 10/3 M, GZM 102 are used for free passage of the flow of working hydraulic fluid in one direction and locking in the opposite direction in the absence of control action and free passage flow in both directions in the presence of control action. The scope of application of hydraulic locks GZM 6 3, GZM 10 3 is hydraulic drives of presses, machine tools, casting and injection molding machines, mobile equipment and other hydraulic equipment. Hydraulic lock GZM6/3M, GZM10/3M, GZM102 of modular installationGZM hydraulic locks 6/3 M, GZM 10/3 M, GZM 102 are used for free passage of the flow of working hydraulic fluid in one direction and locking in the opposite direction in the absence of control action and free passage of flow in both directions in the presence of control action. Scope of application of GZM hydraulic locks 6 3, ГЗМ 10 3 - hydraulic drives of presses, machine tools, foundry and injection molding machines, mobile equipment and other hydraulic equipment. Graphic designation of hydraulic locks ГЗМ Structure of the symbol ГЗМ X/3 М Х ХХХ Х Category of placement Climatic modification: UHL or O Design: no designation - without decompressor Installation method: modular Nominal inlet pressure 32 MPa (320 kg/cm²) Nominal bore, mm: 6, 10, 16, 20 Type of apparatus: hydraulic lock Main characteristics of hydraulic locks GZM 6/3M, GZM 10/3M Name Designation and nominal bore of parameter GZM 6 /3GZM 10/3GZM 102 6 mm10 mmInlet pressure, MPa: - nominal32-maximum35Opening pressure, MPa0.05Flow rate of working fluid, l/min: -nominal3263-maximum80100Design and principle of operation of GZM hydraulic locksGZM 6/3 hydraulic locks (see figure below) and GZM 10/3 (its analogue GZM 102) closes lines A and B when the pressure in the hydraulic system drops; lines P and T (T1 and T2 for GZM-102) are used for the through passage of working fluid from other devices. Hydraulic locks allow you to reliably lock the cylinder cavities both in the event of an accidental drop in pressure in the hydraulic drive, and when the cylinder stops in an intermediate position. To replace the GZM102 hydraulic locks, the production of GZM 10/3 hydraulic locks, 50 mm thick, was launched. The design of these products is completely similar according to the hydraulic circuit. In the GZM 10/3A lock version, line A is locked with control from line B; in the GZM 10/3V version it is the other way around. The main parameters of hydraulic locks are given in the table above. Hydraulic locks KOKHUM-6 (made in Bulgaria) are unified in connection dimensions and diagram with hydraulic lock GZM-6/3. They have a length of 74 mm, a thickness of 39 mm, a nominal pressure of 16 and 32 MPa, a nominal flow of 10 l/min. In most cases, hydraulic locks are installed between the hydraulic distributor and the mounting plate and are sealed together with O-rings placed in the body bores. Hydraulic lock GZM Hydraulic lock GZM (check valve) is used to ensure directed flow of liquid, guaranteed to prevent its reverse movement. Most often, hydraulic locks are used as fuses that prevent the emergency lowering of hydraulic attachments of self-propelled equipment and working parts operating as part of machines for various purposes. The design of a hydraulic lock can be made according to a one- or two-way principle. The difference between them lies in the number of locking and control elements placed in the hydraulic lock body. A one-way device serves only one line, while a two-way hydraulic lock allows you to work with branched hydraulic drive systems. The principle of operation of check valves remains unchanged regardless of the number of locking elements, based entirely on their ability to selectively pass liquid. Within the limits of its operating potential (resistance), the GZM hydraulic lock creates a force that is irresistible by the pressure of the hydraulic flow and opens only upon a signal from the remote control. The design of shut-off and control elements used in hydraulic locks of different resistances can be different, and the higher the back pressure of the hydraulic flow, the more complex it is. Back pressure is the main parameter that is taken into account when choosing hydraulic locks (their resistance should always be higher). An example of a designation for a modular hydraulic lock with a nominal bore of 10 mm for a nominal pressure of 32 MPa, modular installation, shut-off lines in both cylinder hydraulic lines, without a decompressor, for areas with moderate and cold climates, placement category 4: Hydraulic lock GZM-10/3 M UHL4. Hydraulic lock GZM-10/3 Main parameters GZM-10/3 - nominal bore 10 mm; - modular connection to the system; - inlet pressure 32 MPa; - nominal flow rate of working fluid 63/min; Hydraulic lock GZM-6/3 Main parameters GZM -6/3 - nominal diameter 6 mm; - connection to the system is modular; - inlet pressure 32 MPa; - nominal flow rate of working fluid 32 l/min;

No reviews found