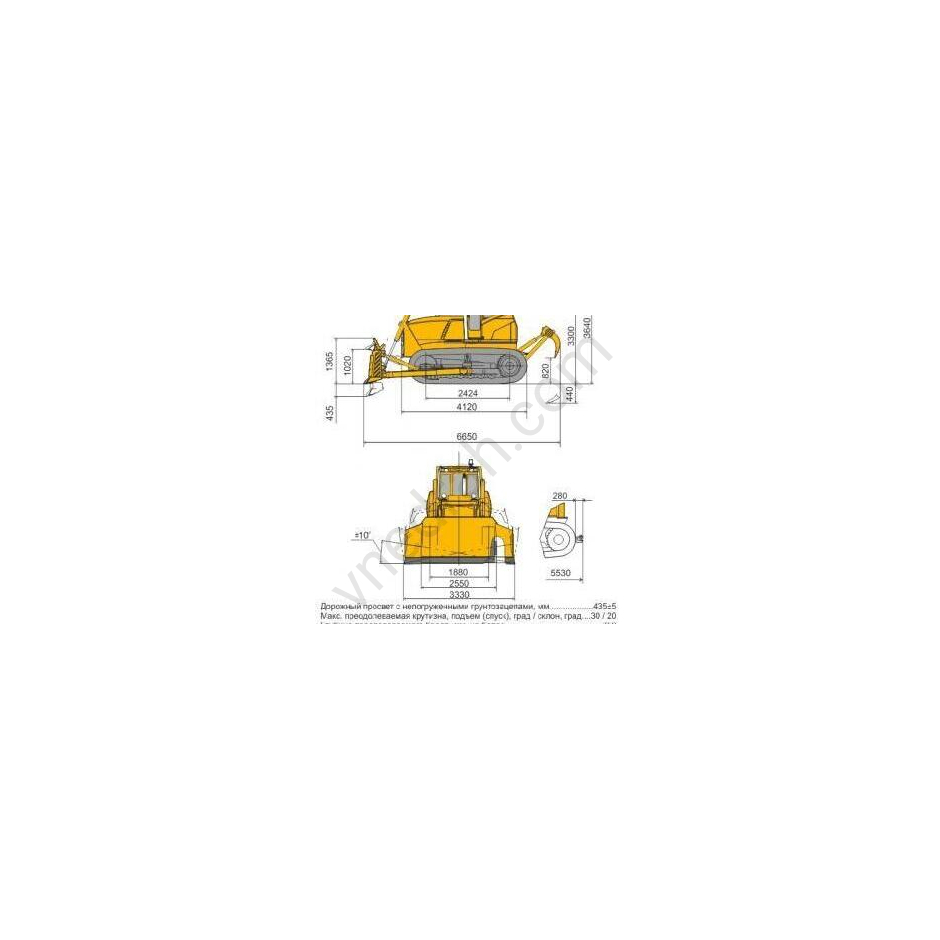

Bulldozer B9.6010ER

The B9.6010ER bulldozer is designed to perform a wide range of work in construction, land reclamation, mining, oil, gas and other industries, to perform excavation work on category I-III soils without preliminary loosening, and IV category soils with preliminary loosening. The B9 bulldozer includes incorporates everything that is best and efficient in the B11 type bulldozer family with new design and technological solutions: a hydromechanical transmission with a remote axis for pumping track bogies - this means an increased transmission life, high productivity, improved working conditions for the operator; frame hexagonal cabin with double-glazed windows, with improved noise-heat-vibration insulation properties, with sliding side windows ensures comfort in the operator’s workplace; for ease of maintenance, the cabin with ROPS-FOPS protection built into it is tilted back using a hydraulic lift; original design using high-strength plastic for lining the cab and tractor hood. The B9 bulldozer is maximally unified with the B11 bulldozer. Distinctive features are: lower weight (19,900 kg), shorter overall length (6,500 cm), lower hourly fuel consumption (savings up to 17%). MODIFICATIONS of Bulldozer B9 are presented in the table: B9.6010E Engine YaMZ-236H-4, GMT, 5-roller bogies, ESSP, tracks with sealed lubricated joint, shoe width 500 mm, planetary gearbox, in-line final drive, engine heater, protection engine and transmission, track derailment guards, installation of operator protection device ROPS-FOPS, ZHPU, hemispherical fixed blade "9E" (without tool box and linings) B9.6010EN YaMZ-236H-4 engine, GMT, 5-roller bogies, ESSP, tracks with a sealed lubricated joint, shoe width 500 mm, planetary gearbox, in-line final drive, engine heater, engine and transmission protection, track derailment guards, installation of a ROPS-FOPS operator protection device, hemispherical fixed blade "9E" (without tool box and linings), 10N - installation of a single-tooth parallelogram type ripper B9B.6000V4 Swamp vehicle, YaMZ-236H-4 engine, GMT, 6-roller bogies, ESSP, tracks with a sealed lubricated hinge, shoe width 900 mm, planetary gearbox, in-line final drive, engine heater, engine and transmission protection, track derailment guards, hexagonal cab, installation of operator protection device ROPS-FOPS, ZhPU, 10B4 - installation of a direct fixed blade for swamp vehicles (without a tool box and pads) Equipment: STANDARD EQUIPMENT • Decelerator. • Air purifier. • Engine and transmission protection. • Operator protection device (ROPS/FOPS). • Silencer. • Adjustable operator's seat with suspension. • Heater - cabin heating fan "Zenith 8000". • Sound signal. • Intermittent reverse sound signal. • Flashing Light. • Cabin with emergency hatch and double-glazed windows. • Window washers. • Exterior rear view mirrors. • Case for first aid kit. • Sun curtain in the cabin. • Lighting system (four front and two rear lights). • Charged batteries (2 pcs), 12 V, 190 A/h (on-board voltage 24V). • Instruments on the instrument panel: - coolant temperature indicator; - engine oil pressure indicator; - engine oil temperature indicator; - on-board voltage indicator; - transmission oil temperature indicator; - transmission oil pressure indicator. • Indicators on the instrument panel: - emergency oil pressure in the engine; - clogged filter in the hydraulic tank; - fuel filter clogged; - air filter clogged; - clogging of the transmission filter; - electric hour meter; - tachometer. • External power and start socket. • Alternating current generator, 1 kW. • Pre-heater "Gidronik 35". • Front tow hooks. • Hydraulic track tensioning mechanism. • Track rollers on plain bearings. • Track with lubricated joint. • Parking brake. • Segmented drive wheel. • Anti-vandal devices. • Fire extinguisher. • Tool kit in a bag. • Guards against derailment of tracks Engine Type Diesel, V-shaped, 4-stroke Model YaMZ-236N-4 Rated power, kW (hp) 145.5 (198) Rated crankshaft speed, rpm 1750 Rated coefficient torque reserve, %, not less than 14 Number of cylinders, pcs./Working volume, l 6/11.15 Cylinder diameter, mm/Piston stroke, mm 215 (158) Specific fuel consumption at operating power, g/kW (h/hp/h) 218 (160) Running system The caterpillar bogies have 6 support rollers on plain bearings with “Duo Cone” seals, as well as two cantilever support rollers with the same seal. Three-point suspension with a balancing beam and pumping of crawler bogies on remote axles. Number of track rollers on each side, pcs 5 Width of track shoes, mm 500 Number of track shoes on each side, pcs 38 Specific ground pressure, MPa 0.070 Tractor frame Frame with reinforced box-section side members, rigid portal with forward attachment points for long-stroke hydraulic cylinders. Transmission Transmission - hydromechanical Hydromechanical: Gearbox - planetary three-speed, reversible with on-the-go shifting. Three-wheel single-stage torque converter. Final drive gear ratio.................................................... ...........................................19.63 Rotation mechanism: side clutches with metal-ceramic friction discs Control................................................... ........................................................ ...hydroserved. Drive wheel................................................... ........................................................ ...sector seals................................................... ...............................Self-clamping “Duo Cone” type Final drives........... ..........................two-stage with spur gears Movement speeds in gears, km/h Forward Reverse I 0 .. 3.96 0 ... 4.67 II 0 ... 6.74 0 ... 7.92 III 0 ... 9.97 0 ... 11.58 Control Rotation mechanisms - permanently closed side clutches with metal-ceramic discs and band brakes with high wear resistance and serrated controls. Operator's workplace Single frame hexagonal cabin of increased rigidity with all-round visibility, meeting the requirements of GOST (ISO) standards for noise and vibration. Reclines with hydraulic lift. Hydraulic system Bulldozer equipment hydraulic cylinders piston diameter/stroke, mm: for lifting 100 / 1250 for blade misalignment 160 / 200 Ripper hydraulic cylinders piston diameter / stroke, mm 160 / 450 Maximum fluid pressure in the hydraulic system (safety valve setting pressure), MPa 20 Hydraulic system Hydraulic cylinders of bulldozer equipment piston diameter/stroke, mm: for lifting 100 / 1250 for blade misalignment 160 / 200 Ripper hydraulic cylinders piston diameter / stroke, mm 160 / 450 Maximum fluid pressure in the hydraulic system (safety valve setting pressure), MPa 20 Electrical equipment Nominal voltage, V 24 Generator 4012.3771-86, pcs 1 Batteries 6ST-190AZ, pcs 2 Tractor weight Tractors, kg 17,200 Tractors with BO, kg 18,650 Tractors with BO, kg 19,900 Tractors with BO and winch, kg 21,150

No reviews found